Source: Lotus West

Author: Tom Dill

Date: 1975

Title: TWINCAM VALVE STEM SEALS

LW# 00EN079

The Twincam head is responsible for much of the high oil consumption in the Lotus. The Ford block pushrod holes are matched with oil drain hole on the inlet side of the head and help greatly in the oil flow back to the sump from the inlet cam "trough”. The exhaust side, however, has no drain holes and the oil must flow forward to the timing chest before returning to the pan. On inlet and exhaust side oil is puddled and is constantly passing over the valve guide. The 0.001" - 0.002" oil clearance typically found in stem to guide provides a quick route for excess oil down the valve stem, on to the valve seats, and into the combustion chamber. The result is carbon buildup on stems, chamber, and exhaust port. Combustion efficiency is lowered, and the Highway Patrol is given smoke signals at frequent intervals.

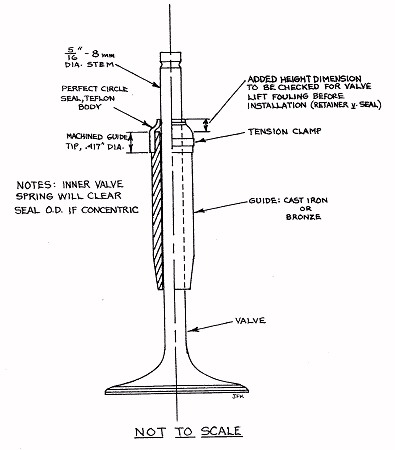

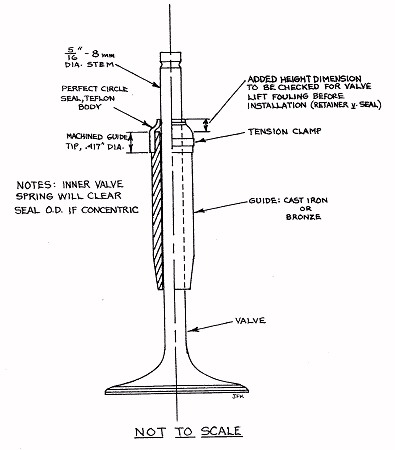

Valve stem seals are rather common and easy to install on typical OHV engines. The guides protrude above the head and are accessible. Twincams are difficult for several reasons: (1) Very little guide tip is exposed topside. (2) No known seal will fit without guide machining. (3) The spring configuration constraints, i.e. ID of inner spring. (4) Net valve lift limits. Despite these difficulties it is possible to install seals on the engine provided some careful checking is done.

Several seals are available to fit modified Twincam guides. The part discussed in this article is the Perfect Circle all-teflon seal which will accept 7/16" or 8 mm stems. The part number is VS-17-18 (#9010) as used on GMC diesels. Special order through distributors is necessary. A set runs about $10 - $15. Apparently specialty "head" shops discovered this seal too as it has been obtained by specifying Pinto 2000 OEM seals. The latter appear to be the same seal with less clamp pressure and are, therefore, easier to press onto the modified guides.

To install, major work is necessary, including machine shop time. The old guides must come out and most likely will be ruined. Bronze or cast iron standard ENFO guides must be machined from 0.500" OD to 0.417" to a depth suitable to accept the body of the seal and its metal spring clamp. The guides are then installed without seals, seats reground, and, finally, seals pressed on from the top. These seals have been used with cam lift of up to 0.400". At this lift, retainer to seal clearance gets very small, however.

It is recommended that before performing these instructions, some measurements be made on several stock set up valves/springs with depth gauges or machinist blue to be certain the necessary clearance will be achieved. Some clearance may be gained by relieving the retainer bottom or slightly repositioning the guide depth. The latter may involve new circlip grooves. Some shops specialize in this type of work, but may not be familiar with the intricacies of the Twincam head.

Proper installation should result in tripling oil mileage or more. One installation of seals resulted in 1500-2000 miles per quart oil consumption compared with a more typical 500-750 mi/qt figure.

Typical Cost Horror Story

Assumption: You strip head and clean.

Guides $20-$40 Valve job, your seats $20

Remove old $10 Seals $15

Machine tips $10 Set up head w. shims $50

Install guides $15 sub $85

Sub $75+

Total $160