Source: Lotus West

Author:

Date:

Title: WEATHER SEALING EUROPA ENGINE COMPARTMENT

LW# 54BI084

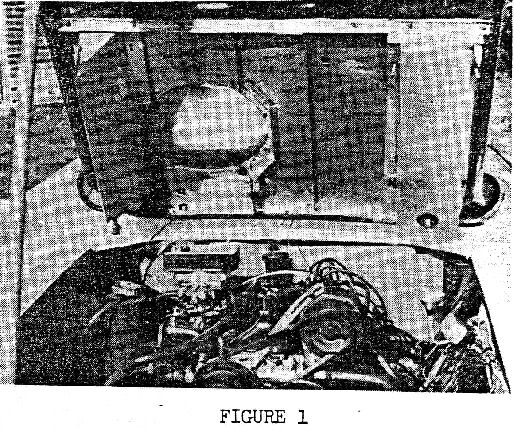

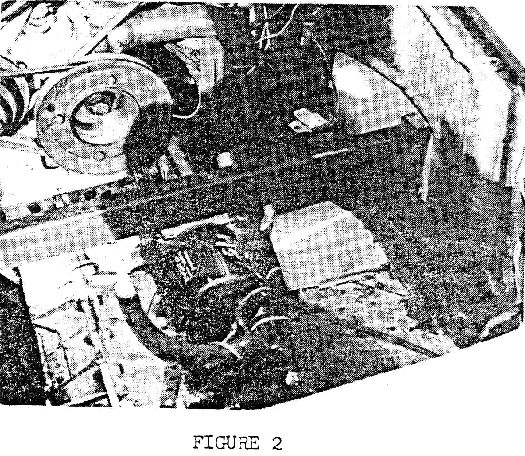

Alas, not all of us can live in SUNNY California - in fact, some of us live in snowy places like upstate New York where corrosion is a real problem. To keep snow, salty slush, water, etc. off the engine, I fabricated some shielding out of sheet aluminum, as shown in the Figures. This consists of 1) a scupper and downspout arrangement to catch water coming through the engine cover ventilation slots, Figure 1; and 2) shielding around the suspension and driveshaft cutouts in the rear wheel wells, Figure 2. The first is more or less applicable to all Europas, while the second is only suitable for the Sl's wrap-around body.

Water, coming in through the four ventilation slots is caught by the two scuppers which are angled forward, the water running out of them into two downspouts that dump into the wheel wells. A similar type of set-up is used on the Porsche 914. The large circular cutout was to clear the air cleaner of the stock carb. The two ridges running down the middle (one of which 'goes around' the cutout) result from a shallow 'U' shaped piece riveted in for stiffness. There is an aluminum right angle piece running along the back edge for the same purpose. The whole affair is held in place by bolts through the sides of the engine cover. Clearances are close all around. The radiator cap has pushed in a spot on the left scupper. The alternator mounting arm has poked itself a hole, and the scuppers Just clear other items. The construction technique is definitely a "cut-and-fit" operation.

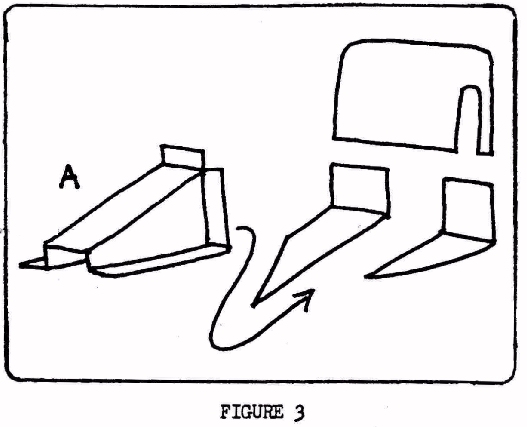

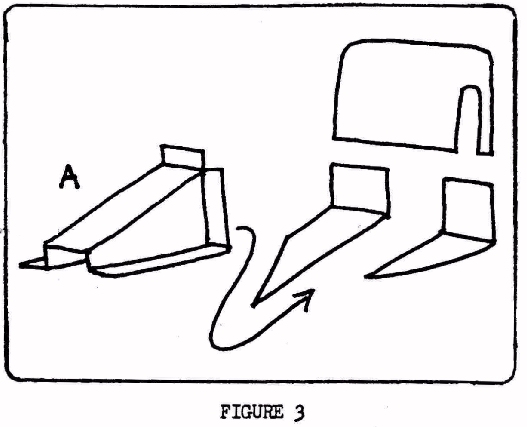

The sheet aluminum fabrication around the driveshafts might be difficult to understand if you're not familiar with the S1. It actually consists of four pieces, as shown in Figure 3. (It was too difficult to make as one piece!) The shielding around the radius arm is a single piece that is the same shape as the driveshaft piece marked "A" in the drawing, but it is much larger. Silver ducting tape was added to further improve the seal. All this shielding is attached with nuts and bolts, although the rear suspension may be removed without disturbing it.

All this shielding has been in place for over two years now, and it really keeps the engine compartment dry no matter what' s happening on the outside. It, of course, restricts ventilation in the summer, but this hasn't been a problem. Not on the car at the time of the photos was a piece of molded rubber garage door seal that is glued to the front edge of the engine compartment (i.e., below the rear window) to keep water from leaking in there.

The aluminum forward of the engine was added to keep the insulation from sagging. It is held in place by two long bolts coming from inside the cockpit (one behind the seat cushion in the S1) through the insulation and aluminum. The aluminum and the scupper's aluminum are grounded and eliminated ignition static on FM - at least until I added a Delta Mk. 10. The license plate mounting plate is also sheet aluminum pop-riveted into place. The two ends of it are bent back at right angles to add rigidity, and the same goes for the insulation support aluminum.

James Scherer Ithaca, NY