Source: Lotus West

Author: Jim Fraser

Date:

Title: EUROPA CHOKE ASSEMBLY FOR WEBERS

LW# 54FU059

A couple of years ago I had a 28/36 DCD Weber installed and not to long after I realized I required the use of the chokes as the engine could not idle at all when cold. The attached drawings are the design I ended up with, and I must say it has worked perfectly. Having use of a machine shop made its manufacture quite simple, but any piece can be made at home by substituting materials.

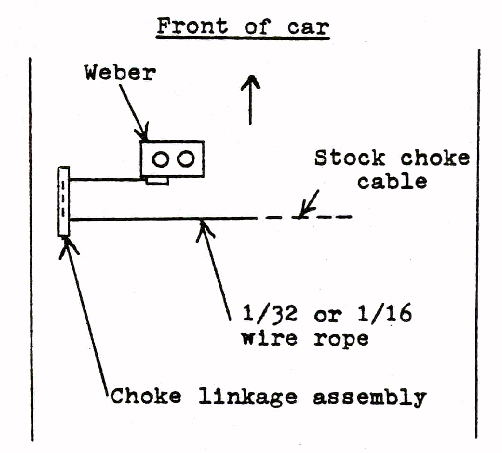

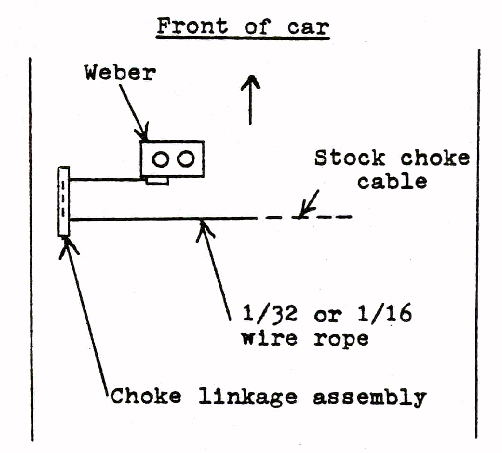

The unit operated by mounting it in a horizontal position (with the use of the bevel washers) in a flat plane between the choke arm on the Weber and the stock Solex choke cable. The 3-1/4" distance between rollers is approximately the distance from the Weber choke to the stock choke cable. In other words a rectangle is created as such:

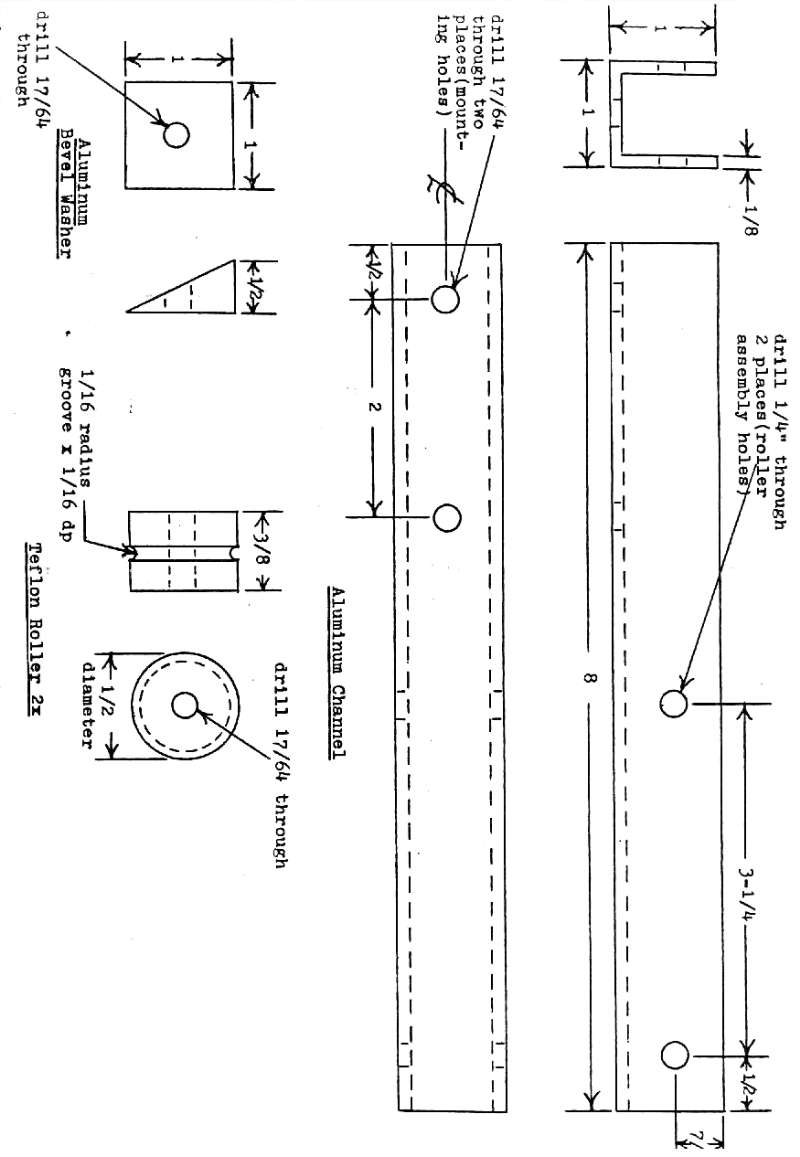

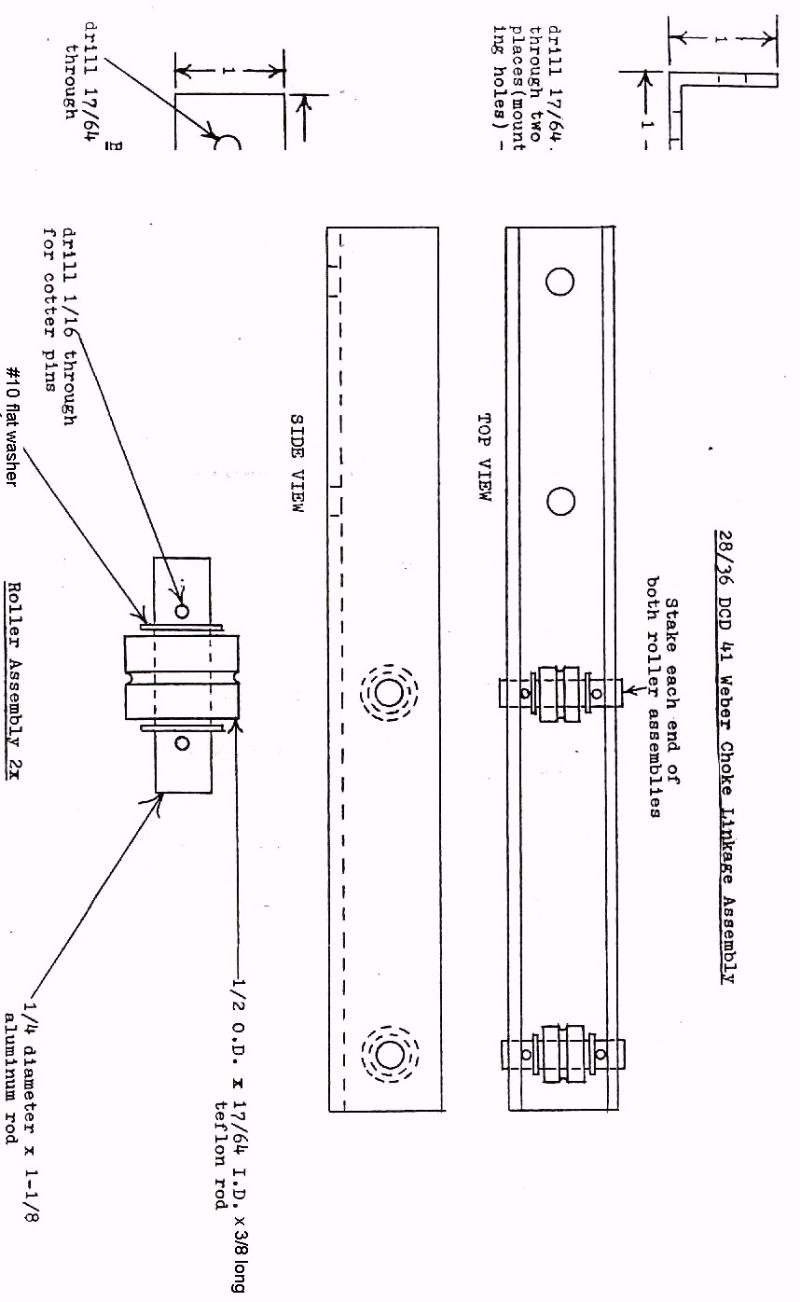

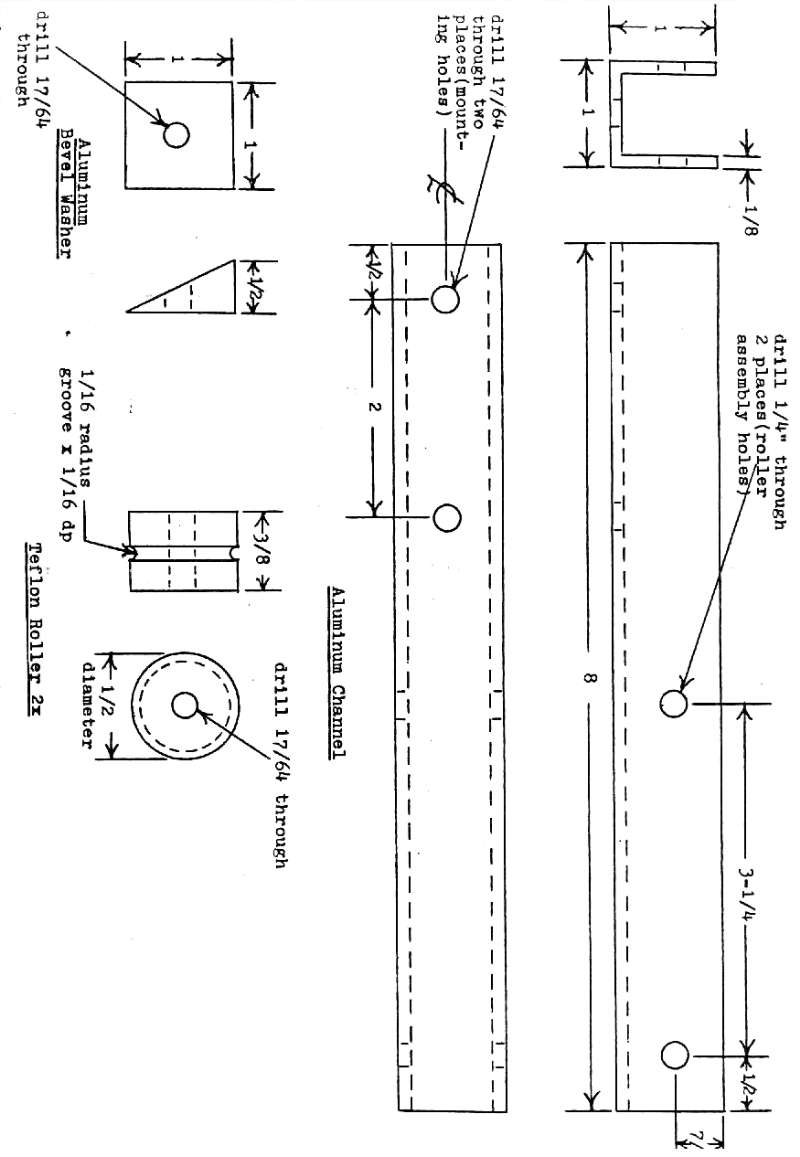

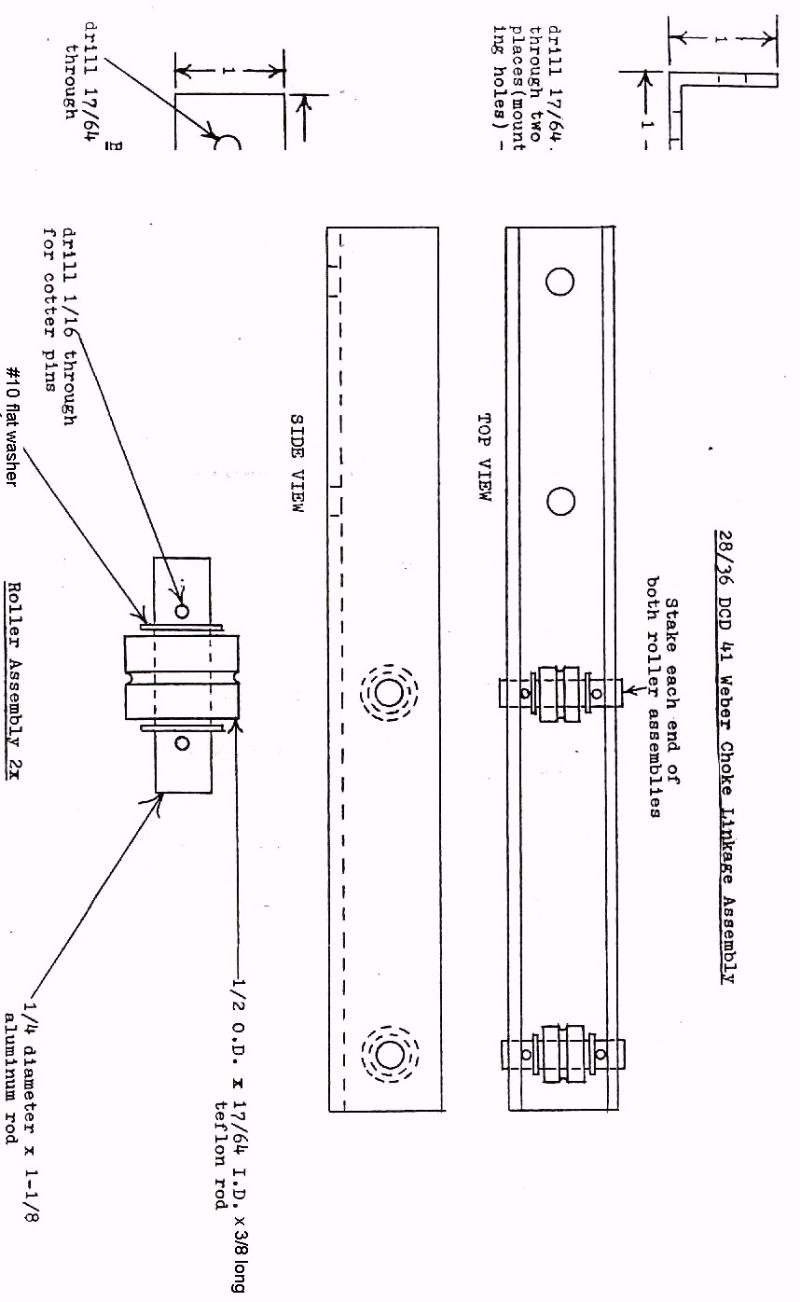

Assemble the linkage assembly as follows: insert 1/4" axle through one wall of channel, slide on one #10 flat washer, one roller, a second flat washer, then push axle on through other wall of channel leaving about 1/16" protruding through both walls and stake in place at this time with a center punch. This leaves the cotter pins to be inserted to retain the roller in place. Ensure it spins freely on the axle.

Next, mount the unit on the inner wheel well in the flat plane previously described by transferring ~e hole pattern and drilling the 17/64" clearance holes for the 1/4" mounting screws.

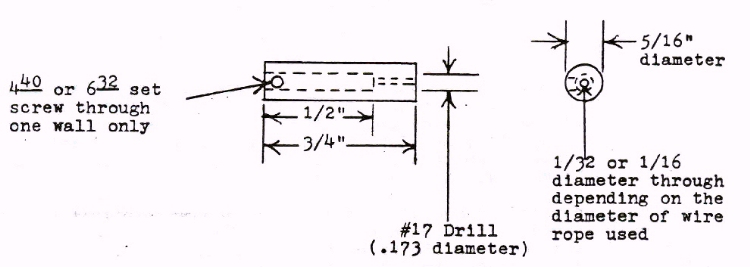

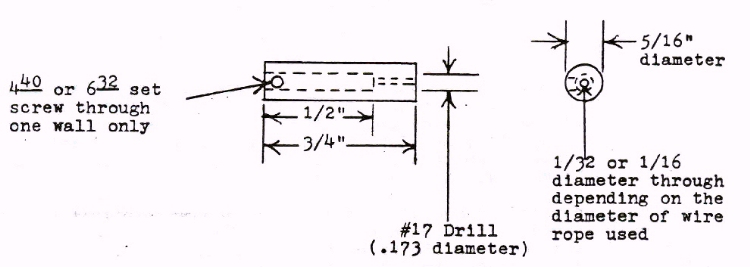

After the unit is securely mounted in your car, attach one end of the wire rope to the Weber by the clamp screw provided, thread the other end under the two rollers in their grooves, and attach to the stock choke cable solid end by means of the following simple adapter:

Simply insert the open end of the wire rope through the small hole and tie a double knot or drop a glob of solder on it to ensure not pulling back through. Take up the slack at the clamp screw on the Weber. One thing remains. Since the Weber has a return spring on the choke arm, it is necessary to make a wedge to use in the cockpit to keep the choke in the desired position. I took a piece of thin-walled i/4" O.D. steel tubing 5/8" long, split it in half, and used one half to wedge between the front of the armrest padding and the choke knob rod. It's rough, but effective.

Not knowing much about other street Webers, it seems to me any carb with the same type of choke may well be able to use such a mechanism as I've offered.

Material List

1. One piece 1 x 1 x 1/8" aluminum channel x 8 long

2. Two each ¼ diameter aluminum rod x 1-1/8 long

3. Two each 1/2 diameter Teflon rod x 3/8 long

4. Four each #10 flat washer

5- Four each 1/16 cotter pin x 1/2 long

6. Two each ¼ 20 hex head cap screw x 1 long

7. Two each ¼ 20 hex nut

8. Two each ¼ split lock washer

9. Two each ¼ aluminum bevel washer

10. One piece 1/32 or 1/16 diameter wire rope (stranded cable) x approximately 2' long