Source: Lotus West

Author:

Date:

Title: PRE-TC EUROPA GAS CAPACITY INCREASED

LW# 54FU069

The recent fuel shortage caused some anguish to me (and others) and my low gas capacity Europa Series 2. While the achieved gas mileage was gratifying, the search for available gas and waiting to obtain same was most frustrating (remember?). During this period the Europa and I were commuting weekly between Downey and my home in Santa Maria.

These frustrations were dispelled this past spring by: l) the gas shortage mysteriously vanished; 2) the Downey/Santa Maria commute was terminated; and 3) the gas capacity of the subject Europa was approximately doubled. The latter item is the subject of this article.

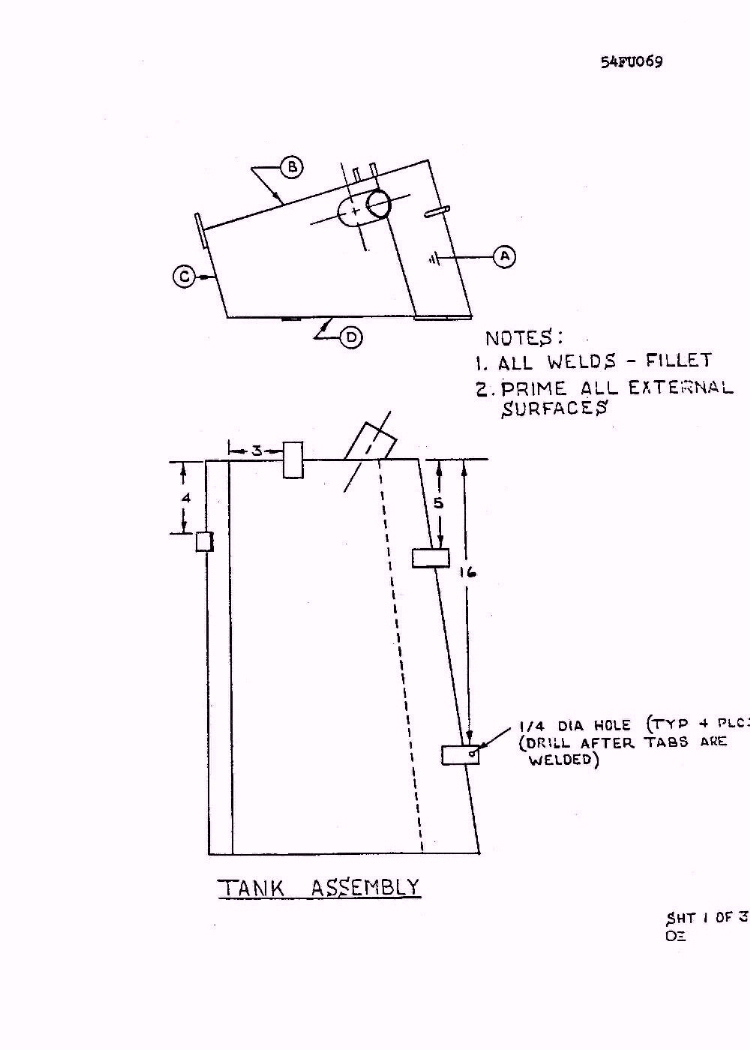

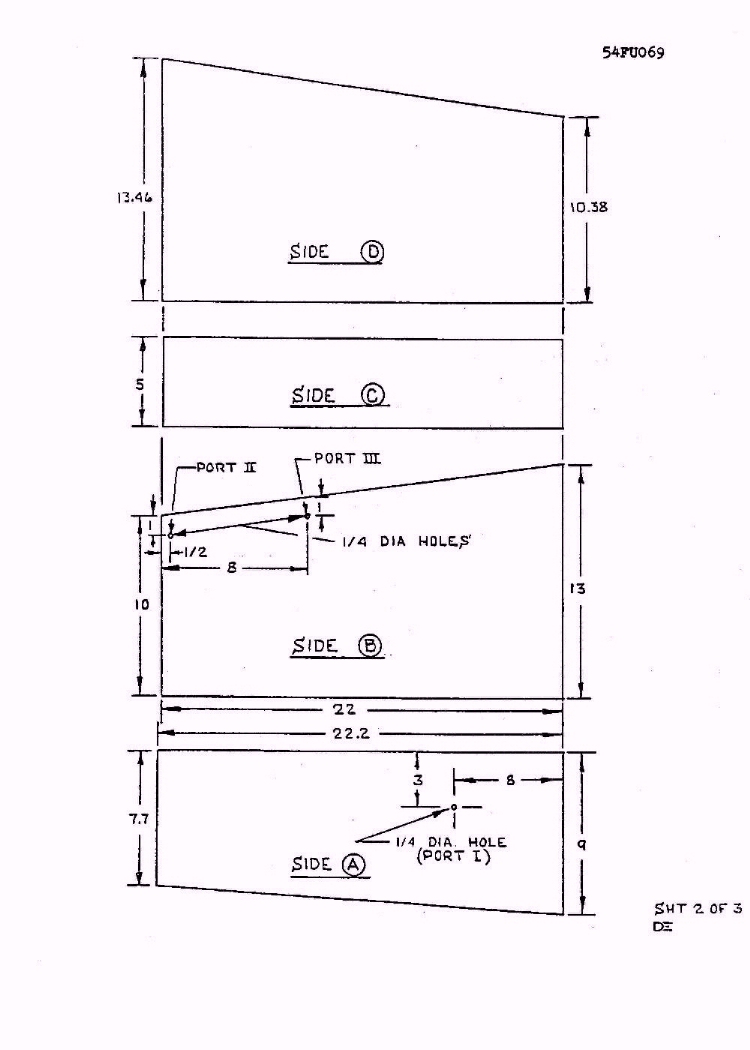

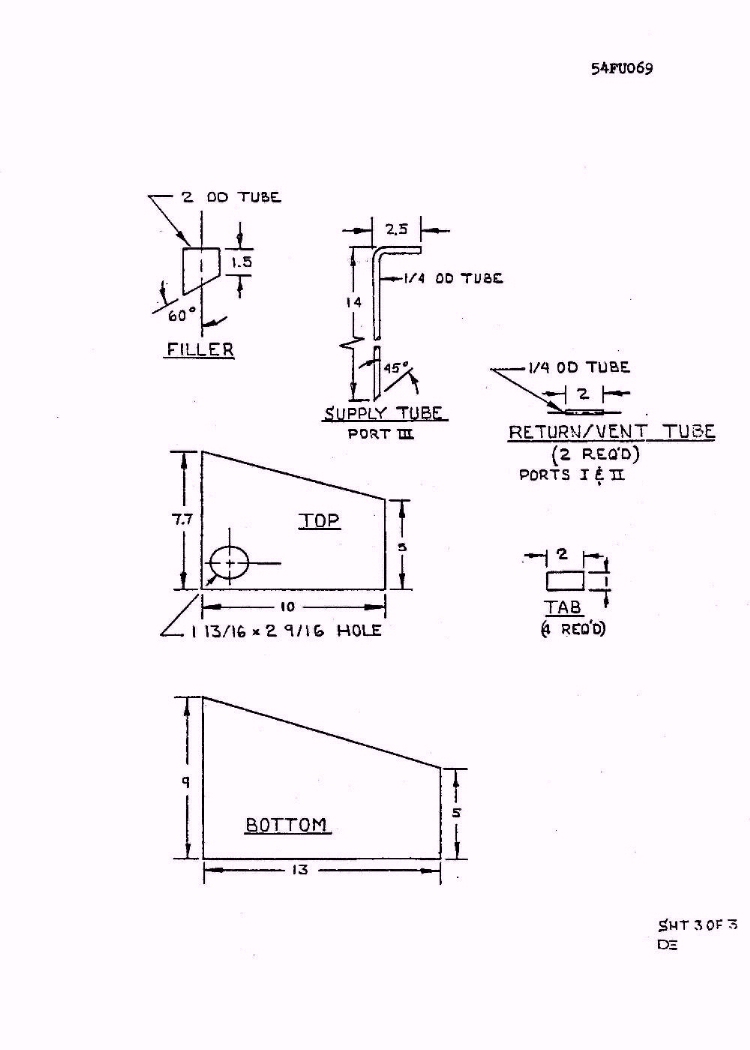

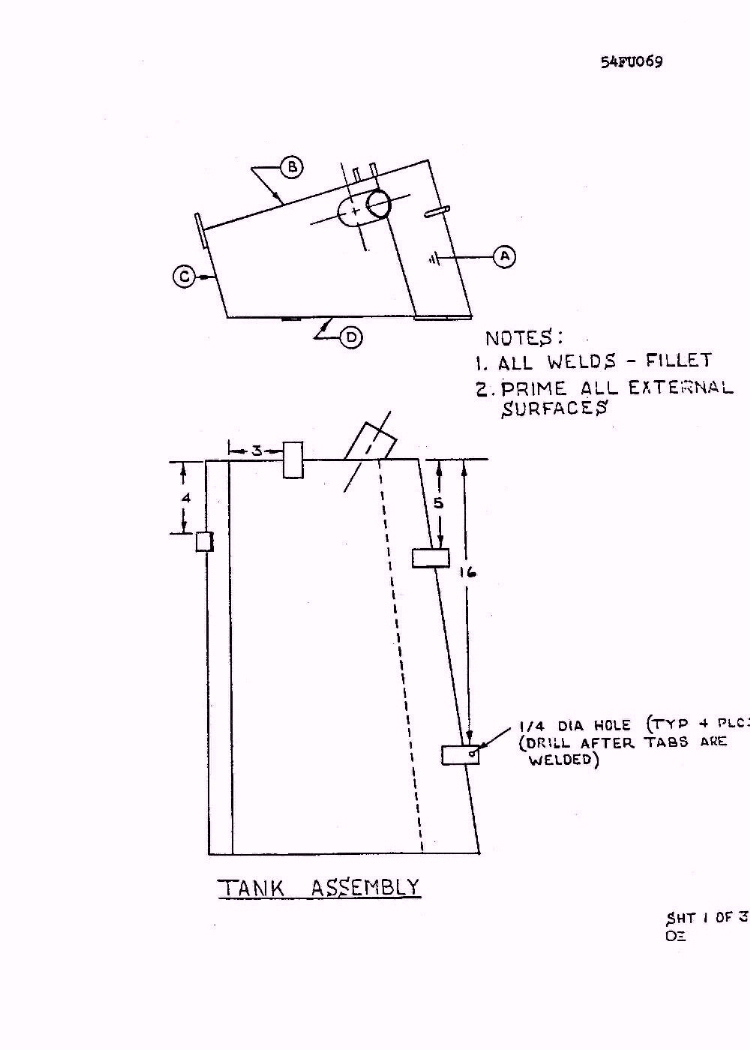

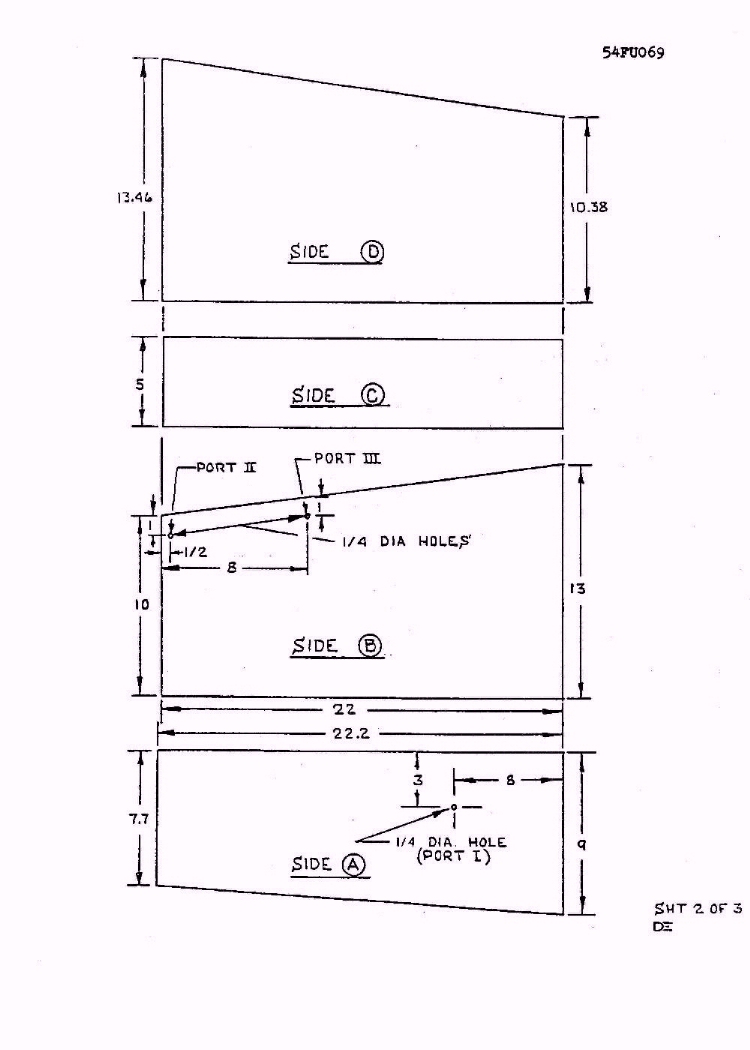

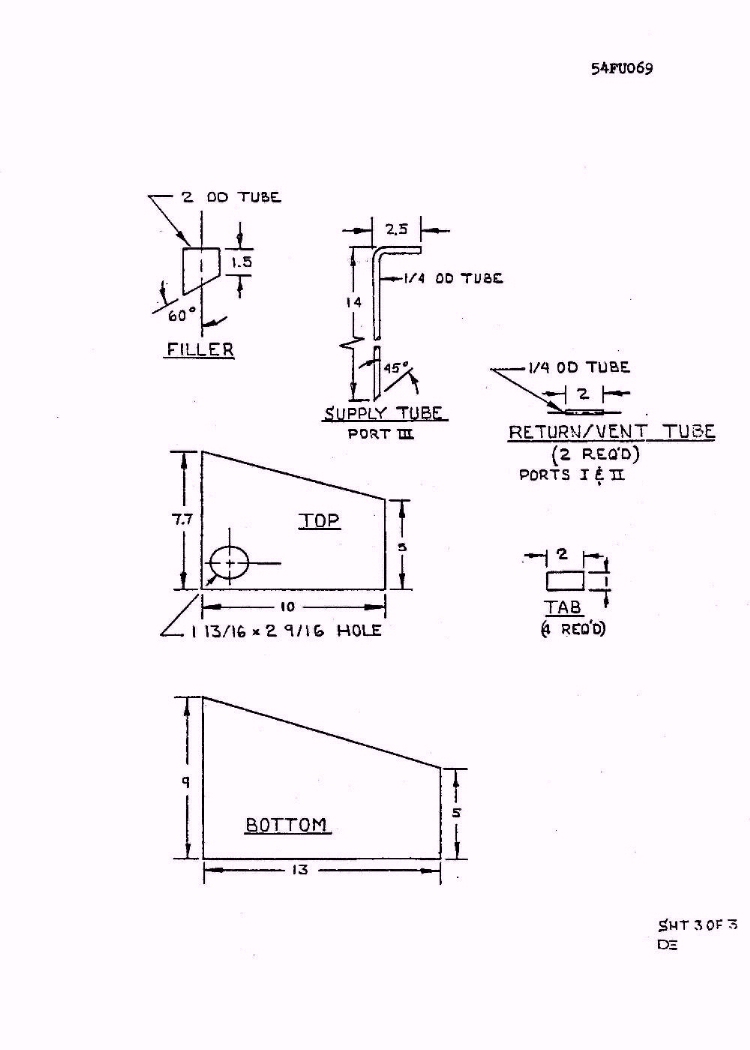

A new gas tank has been nicely installed just forward of the right-rear wheel well opposite the existing tank (similar to the TC installation). The new tank configuration (i.e., shape) is a mirror image of the existing left-hand tank. The new tank mounting tabs and tank penetrations are located similarly as on the existing tank. The new tank is welded up from 0.090 inch thick 6061-T6 aluminum sheet. The aluminum was selected not only because of its low weight but also because of its no-cost (surplus) availability (I thought there had to be at least some small advantage of being associated with the Aerospace Industry). Mounting tabs and penetration tubes are similarly 6061-T6 aluminum and welded to the tank shell. A 5 psig leak check of the tank was accomplished prior to the installation.

The modifications to the Europa to accept the new tank were minimal and consisted of:

l)A little saber saw action was required to remove a fiberglass section from the right side bottom pan to allow insertion of the tank from that position. The resultant cutout resembles that on the left side.

2)The ignition coil was relocated from the forward face of the right-rear wheel well to the inboard wheel well panel. This relocation subsequently required a ventilated drip shield to be placed over the coil assembly to prevent drowning during car washes or rains. The shield is made from polystyrene foam and is hinged to the wheel well panel for easy access to the coil.

3)Three attach mounts were installed on the right hand inner side panel. The mounts are made of moly-screws brazed to 1-1/2 inch diameter steel washers. Holes were drilled in the side panel, the mounts were inserted into the holes, and the moly-screws were tightened. Two l-ply fiberglass doublers, approximately 4x4 inches, were then bonded to the exposed washer faces and surrounding panel surfaces. Holes through the doublers were maintained to admit the bolts for tank mounting. Washers were used to shim between these mounts and the tank attach tabs.

4)A 1/4 inch diameter hole was drilled through the forward face of the wheel well, near where the ignition coil had previously been positioned, to accept the aft tab attach bolt.

5)Three tees were fabricated (brazed) of 1/4 inch 304L stainless steel tubing (another very small advantage of ...). The tees manifold the new-tank fuel pump supply hose, fuel pump return hose, and tank vent hose with the appropriate existing Europa hoses.

6)A 2-3/4 inch hole was drilled (i.e., "hogged") in the aft deck, opposite the existing gas fill assembly to accept a fill neck and rubber grommet. The fill neck was fashioned from a 2 inch diameter wrecking yard supplied fill neck (origin unknown). The straight filler tube was cut on a bias, rotated 180°, and re-welded to provide alignment between the fill neck and the canted fill tube on the top of the tank. These were then interconnected with a straight piece of 2 inch hose and clamps.

Performance of the additional tank has been very satisfactory. No effects of added right side weight, estimated at 60 pounds with the tank filled, have been noticed. Manifolding of the two tank supplies and tank returns has produced nearly equal tank use rates and, hence, the utilization of the existing gas gauge for the two tanks has been satisfactory. The right-hand tank does appear to supply gas at a slightly faster rate than the left-hand tank. Because of this, a small petcock will be added to the right-hand tank supply and to the right-hand tank return lines. This will permit right-hand tank isolation if required. Tank cross feed during filling is slow enough that both tanks may be serially filled to capacity.

Working sketches of the tank assembly, which may be fabricated from steel as well as aluminum, can be obtained by sending a stamped self-addressed envelope to Dave Erickson, 11825 Strand Drive, Apt. 7, Florissant, Missouri 63033. The Aerospace Industry also has its small disadvantages (such as transfers). Anyway, there won't be any more commutes to Downey!