Source: Lotus West

Author:

Date: 1975

Title: 1975 LOTUS EUROPA CLINIC ANNUAL

LW# 54MC081

ENGINE

EUROPA CHOKE CABLE ATTACHMENT - Problem: I never seem to be able to remember which way I had turned the choke control when I set the choke, and as a result broke two cables by twisting them off at the carbs.

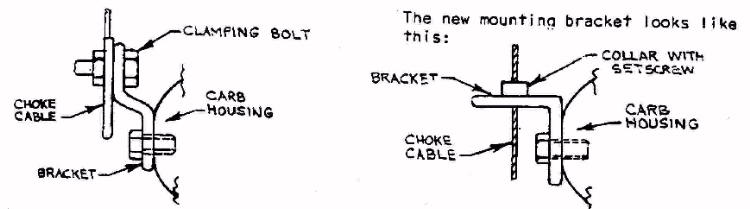

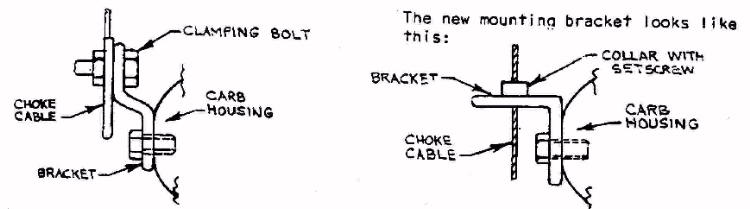

Solution: Rather than change my ways, I replaced the fixed mount for the choke cable at the carburetor with a swiveling mount. The original attachment (which is on the front carburetor) looked somewhat like this:

The collar with set screw is the type the model airplane people use to hold wheels on axles. They cost about 75¢ for four (and the Allen wrench comes free) and they come in several sizes, Bring the choke cable into a hobby shop and try all the sizes for the best fit, The brand I bought is Dura-Collar by Du-Bro. The bracket is made out of a piece of thin wall square tubing angle iron, or aluminum, or thick sheet metal and drilled to fit the carburetor mounting pin and bolt. Now the choke cable spins freely and doesn't twist and untwist each time the choke is used.

Merl Thurman

Sacramento, Ca.

ELECTRICAL

Europa Ignition Switch Assembly

Problem: The ignition switch assembly is a two-piece structure. The first (front) part (where the key goes) has the lock and key and the steering wheel lock parts in it. The second part has all of the electrical switches in it. The two parts are held together by a plastic cover that looks somewhat like a miniature shift lever boot. I discovered that when the plastic cover splits, the two parts fall away from each other. I also discovered that the local friendly Lotus dealer can (or will) not supply just the plastic cover -- but only the whole assembly (which costs in excess of $20).

Solution: Clamp a radiator hose clamp around the plastic cover at the wide end (toward the key). This will not only fix a broken cover but should also prevent one from breaking.

Merl Thurman

Sacramento, Ca.

Problem: Minute hairline spiderwebbing of interior of Dist. Cap. not visible from exterior. Add heavy rain, result dead car in the "toolies". Owner suggests careful inspection not only of the Dist. Cap. but all the essential wiring and their terminals and connections.

Discovered a piece of preventative maintenance for Europa Owners. Using a spray can of LPS-I (or equivalent), a liquid non-silicone penetrating lubricant, with extension tube, spray a few seconds blast up through the casting hole in the rear hub carrier; displaces water, prevents rusting of the splines and greatly aids disassembly.

Long standing wandering fuel gauge plus the time to investigate equals solution. Gauge and wiring checked out fine; pulled sending unit from tank (without tank removal as speced in Shop manual), r across terminals was erratic when float was jiggled from side to side. Unbend three tabs, disassemble, wiper in poor contact, slight bend in same for increased spring contact, reassemble, reinsert. Product: Accurate gas gauge.

Could have ordered a new one, but about an hour's time saved the wait and expense of the new unit.

Later, drifting oil pressure readings led to discovery of large amount of green corrosion on the sending unit connector. Cleaning and attaching to other terminal of sending unit restored full stable oil pressure. (Cheaper

than a bearing job. Ed.)

Lastly, necessity to replace the heater control cable arose. Factory routing included contact with exhaust manifold; heat and rubbing led to severance of outer cable. I feel there must be a better answer, like rerouting or at least banding at points of contact.

Jim Fraser

That LPS-I, or WD-40 if you rather, might have gotten you home on that rainy night. Serial, a goo blast of that jazz in the dist. cap will displace beaucoup HOH and make a soggy ignition do its thing again.. carry it with you and give it a go..

Ed.

SUSPENSION

EUROPA BRAKES: The Europa shop manual recommends that every 40,000 miles-3 yrs. the brake system be completely overhauled; new washers, seals, hoses, fluid. This seemed a bit much to me, but having a 1967 S1 with 44,500 miles, it was always in the back of my mind, even though my brakes worked fine and were not leaking fluid. So, I finally took everything apart and found it all to be in incredibly good condition, not even in need of a rebuild. But I did rebuild them since I had purchased the kits. Kits are Girling and part numbers are: front caliper rebuild kit, SP 2697; rear wheel cyl. rebuild kit, SP 2027/4, I was unable to get a rebuild kit for the master cylinder locally. Front pads are Girling 64327636~ GBD 538.

EUROPA REAR WHEEL BEARINGS: As you might already know, the outer rear wheel bearings in the Europa may be replaced by a domestically produced bearing by taking it to an auto parts store and having it matched. If you are a person who likes to have parts in hand before getting started, a suitable replacement is: Delco NDH Bearing I #Z99506 Ball Bearing 954851 D. This is in fact the bearing Lotus East will send you if you order it from them (as I did) and the number was taken off of the box.

James B. Scherer

EUROPA FRONT WHEEL BEARING DUST COVERS

Problem: The front wheel bearing dust covers are difficult to remove without destroying them. There must be a trick to it that I haven't discovered. I have discovered, however, a way to avoid the whole problem.

Solution: The solution I found is to drill out the threaded hole to 1/4", flatten the top of the cover, and weld a 3/16" nut onto the flattened spot.

The finished product should look like this:

A handy jig for holding the nut in place while welding looks like this:

To remove these dust covers, just run a 3/16" bolt into the dust cover. The bolt will hit the end of the spindle and the dust cover will pull right out.

This solution will work for Europa Twincams (and Triumph Spitfires). It will probably work for other models of Lotus.

Merl Thurman

Sacramento, Ca.